History

The fib was formed in 1998 by the merger of the Euro-International Committee for Concrete (the CEB) and the International Federation for Pre-stressing (the FIP). These predecessor organizations existed independently since 1953 and 1952, respectively.

- Brief history

- CEB Presidents

- FIP Presidents

- CEB Plenary Sessions

- FIP Congresses

- FIP Symposia

- CEB & FIP Awards

-

Brief history of the fib's parent associations, CEB and FIP from 1952 to 1998

Years History 1998 On the 24th May 1998 the CEB Administrative Council, following the resolution taken by the last General Assembly in 1997, dissolved the CEB in favour of the fib with an effective date of 28th May 1998. In a parallel move the same day, the FIP Council, following the resolution taken by the last General Assembly in 1996, dissolved the FIP in favour of the fib with an effective date of 28th May 1998 (the last day of the XIII FIP Congress Amsterdam). 1997 The 31st CEB General Assembly in Stockholm in June 1997, following a suggestion made by a common CEB-FIP Implementation Group, approved the merger with FIP to create fib. 1996 The FIP General Assembly met in London in September 1996 during the FIP Symposium, and following a suggestion made by a common CEB-FIP Implementation Group, approved the merger with the CEB to create the fib. 1991 The Final Draft of the 1990 CEB-FIP Model Code was presented to and endorsed by CEB's 28th Plenary Session in Vienna. Restructuring of CEB's Commissions and Task Groups commenced. 1985 The Model Code for Seismic Design of Concrete Structures was published by CEB. A decision was made to compile a 'Model Code 1990'. The secretariat of FIP moved from C&CA to The Institution of Structural Engineers, with Dr. Ralph Andrew succeeding Barry W. Shacklock as Seretary General. 1983 On invitation of the EPFL (Ecole Polytechnique Fédérale de Lausanne), CEB's Lausanne office was opened, which became in 1985 the CEB headquarters after closure of the Paris office. 1980 CEB's legal domicile was transferred to Geneva, Switzerland. 1978 Barry W. Shacklock, who was at the time Director of Administration Services at C&CA, was appointed Secretary-General and Treasurer of the FIP, succeeding Mr. Arthur W. Hill. 1978 The first volumes of the 'International System of Unified Standard Codes of Practice for Structures' were published: - Volume I: Common unified rules for different types of construction and material

- Volume II: CEB-FIP Model Code for Concrete Structures

1977 The 19th CEB Plenary Session in Granada approved the final draft of what later became the 'CEB-FIP Model Code 1978'. 1976 CEB's name changed to 'Comité euro-international du béton' (Euro-International Committee for Concrete). 1974 An initiative by CEB – in a concentrated effort and in conjunction with FIP, ECCS, CIB and RILEM – created an 'International System of Unified Standard Codes of Practice for Structures', in which CEB became responsible for the common unified rules for different types of construction and material and the model code for concrete structures. 1970 The second edition of what later became the "CEB-FIP International Recommendations” were ratified by the two associations, covering structures in plain, reinforced and prestressed concrete. In the following years elaboration of numerous accompanying manuals. 1970 The second edition of what later became the "CEB-FIP International Recommendations” were ratified by the two associations, covering structures in plain, reinforced and prestressed concrete. In the following years elaboration of numerous accompanying manuals. 1968 The importance of the results achieved by CEB was officially recognised by the United Nations in the publishing of the UNESCO 'Code et manuel d'application pour le calcul et l'exécution du béton armé', conceived especially for the developing countries, based on the 1964 CEB International Recommendations and elaborated by a commission of CEB experts. 1967 FIP-Notes created as a means of dissemination of news among members, continued until 1998. 1964 The First CEB International Recommendations (covering reinforced concrete structures), was published successively in fifteen languages as 'a tentative draft for a complete set of provisional practical recommendations relating to all aspects of design and construction', and contributed very efficiently to the progress of drafting of national codes in about twenty countries. 1962 A common initiative by FIP and CEB created a 'Mixed CEB-FIP Committee for Drafting of Recommendations for Prestressed Concrete'. 1961 On the initiative of CEB the 'Liaison Committee for the International Civil Engineering Associations', was created (comprising still today the CIB, ECCS, fib, IABSE and RILEM), with the aim to define the areas of activity and to harmonize the endeavours. Under the auspices of the Liaison Committee, several joint undertakings with other associations could be initiated, among them the creation of a joint CEB-CIB-RILEM Commission on Statistical Quality Control (see CEB Bulletin 110) and in 1971 of the still existing Joint Committee on Structural Safety (JCSS). 1959 In CEB the priority of future work was given to ‘the elaboration of easily usable (international) practical rules (recommendations), with possibly limited initial application or selection of a sufficient security, followed by improvement of the rules when research results permit’. By this decision, the objectives of CEB had to be re-defined as: - coordinating and synthesizing research for all problems related to technology and innovation in structural concrete;

- creating and orchestrating the international principles and rules for the conception, calculation, construction and maintenance of concrete structures; and

- establishing codes, standards or other regulatory documents on a unified international basis progressively, through successive stages. For these purposes the first 'Working Commissions' were created.

1957 Beginning of CEB's technical publication series 'Bulletins d'Information', continued until No. 243 in 1998. 1954 Philip Gooding, Director-General of the Cement & Concrete Association was appointed Secretary General of FIP. Subsequently, C&CA in Wexham Springs, UK, hosted and sponsored the secretariat. 1953 The Comité européen du béton CEB (European Committee for Concrete) was founded, on an initiative of French contractors, by André Balency-Béarn (France), Louis Baes (Belgium), Emile Nennig (Luxembourg), Hubert Rüsch (Germany), Euardo Torroja (Spain) and Georg Wästlund (Sweden). The French National Federation of Building (FNB / SNBATI) in Paris hosted and sponsored the secretariat. Yves Saillard was nominated as Secrétaire Permanent, and later became (1968) Vice-Président Délégué and (1971) Président Délégué. 1952 The Fédération internationale de la précontrainte FIP (International Federation for Prestressing) was inaugurated at an international meeting held in Cambridge, England. -

CEB Presidents from 1953 to 1998

Presidency CEB Presidents 1987-1998 Roy E. Rowe (United Kingdom) 1983-1987 Theodossios P. Tassios (Greece) 1979-1983 Julio Ferry-Borges (Portugal) 1971-1978 Andrew Short (United Kingdom) 1968-1971 Hubert Rüsch (Germany) 1957-1968 Franco Levi (Italy) 1953-1957 André Balency-Béarn (France) -

FIP Presidents from 1953 to 1998

Presidency FIP Presidents 1996-1998 Michel Virlogeux (France) 1992-1996 Jan Moksnes (Norway) 1988-1992 René Walther (Switzerland) 1984-1988 Hans Wittfoht (Germany) 1982-1984 John Derrington (United Kingdom) 1978-1982 Roger Lacroix (France) 1974-1978 Ben C. Gerwick Jr. (USA) 1970-1974 Gerrit F. Janssonius (Netherlands) 1966-1970 Franco Levi (Italy) 1961-1966 Yves Guyon (France) 1958-1961 Eduardo Torroja (Spain) 1953-1958 Eugène Freyssinet (France) -

CEB Plenary Sessions

Sessions Luxembourg (1953), Fontainebleau (1954), Madrid (1956), Rome (1957), Vienna (1959) Monaco (1961), Luxembourg (1962), Wiesbaden (1963), Ankara (1964), London (1965), Brussels (1966), Lausanne (1968), Delft-Scheveningen (1969) Copenhagen (1971), Leningrad (1972), London (1973), Lisbon (1975), Athens (1976), Granada (1977), Rome (1979) Budapest (1980), Munich (1982), Prague (1983), Rotterdam (1985), Treviso (1987), Dubrovnik (1988) Paris (1990), Vienna (1991), Les Diablerets (1993), Berlin (1995), Stockholm (1997) -

FIP Congresses

Congresses Amsterdam (1998), Washington (1994), Hamburg (1990) New Delhi (1986), Stockholm (1982) London (1978), New York (1974), Prague (1970) Paris (1966), Rome and Naples (1962) Berlin (1958), Amsterdam (1955), London (1953) -

FIP Symposia

Symposia Beijing (1991), Budapest (1992), Kyoto (1993), Brisbane (1995), London (1996), Johannesburg (1997) Bucharest (1980), Calgary (1984), Jerusalem (1988) Tbilisi (1972), Sydney (1976) Madrid (1968) -

FIP Freyssinet Medal

Years Medalists 1998 Jan Moksnes (Norway) Jean Muller (France) 1994 Alexander C. Scordelis (USA) Hans Wittfoht (Germany) René Walther (Switzerland) 1990 Christian Menn (Switzerland) Jörg Schlaich (Germany) 1986 Shunji Inomata (Japan) Roger Lacroix (France) 1982 Max Birkenmeier (Switzerland) Ben C. Gerwick Jr. (USA) 1978 Paul Abeles (USA) Alexei A. Gvozdev (USSR) Franco Levi (Italy) 1974 Fritz Leonhardt (Germany) T'ung-Yen Lin (USA) Victor V. Mikhailov (USSR) 1970 Nicolas Esquillan (France) Ulrich Finsterwalder (Germany) Ricardo Morandi (Italy) FIP MedallistsYears Medallists 1998 Mineo Morimoto (Japan) Armando Rito (Portugal) Joost Walraven (The Netherlands) 1997 Charles Liebenberg (South Africa) Robert Park (New Zealand) 1996 Tom W. Kirkbride (United Kingdom) Javier Manterola (Spain) 1995 W. G. J. Ryan (Australia) Steinar Helland (Norway) 1994 Norman C. Scott (USA) Arnold van Acker (Belgium) 1993 Shoji Ikeda (Japan) Hans Rudolf Müller (Switzerland) Hiroshi Muguruma (Japan) 1992 Lajos Garay (Hungary) Peter Matt (Switzerland) Géza Tassi (Hungary) 1991 He Guangqian (China) Henk J. C. Oud (The Netherlands) 1990 Helmut Bomhard (Germany) John E. Breen (USA) Michel Placidi (France) 1988 Carlo Cestelli Guidi (Italy) Lubor Janda (Czech Republic) Jacob Shimoni (Israel) 1986 C. R. Alimchandani (India) Helmut F. Cabjolsky (Argentina) Jacques Mathivat (France) Tippur N. Subba Rao (India) J. H. van Loenen (The Netherlands) 1984 Karl G. Bernander (Sweden) A. S. G. Bruggeling (The Netherlands) Kai Holbek (USA) Konstantin V. Mikhailov (USSR) 1982 Gerrit F. Janssonius (The Netherlands) Michel Kavyrchine (France) Kyoshi Nakano (Japan) Sven-Erik Svensson (Sweden) 1980 Constantin Avram (Romania) Olav Olsen (Norway) 1978 Jan Bobrowski (United Kingdom) Carlos F. Casado (Spain) Alexandra B. Druganova (USSR) Jean Muller (France) Hans Wittfoht (Germany) Silvano Zorzi (Italy) 1976 William P. Brown (Australia) Armand H. Gustaferro (USA) 1974 Arthur A. Anderson (USA) Shunji Inomata (Japan) David J. Lee (UK) 1970 Dudley H. New (United Kingdom) Pierre Xercavins (France) Branko Zezelj (Yugoslavia) CEB Honorary Life MembersYears Medallists 1997 Giorgio Macchi (Italy) Henri Motteu (Belgium) 1993 Henri Mathieu (France) Manfred Stiller (Germany) 1988 Yves Saillard (France) 1983 Troels Brøndum-Nielsen (Denmark) 1980 Alexei A. Gvozdev (USSR) 1979 Nicolas Esquillan (France) 1977 Fritz Leonhardt (Germany) FIP Honorary Life MembersYears Medallists 1998 Rafael Pineiro Abril (Spain) 1992 Ralph P. Andrew (United Kingdom) 1990 Roy E. Rowe (United Kingdom) Manfred Stiller (Germany) 1988 Konstantin V. Mikhailov (USSR) 1986 William F. G. Crozier (United Kingdom) Barry W. Shacklock (United Kingdom) 1978 Karl Kordina (Germany) Fernand Dumas (France) 1974 Sir Alan Harris (United Kingdom) Jiri Klimes (Czechoslovakia) 1970 Carlo Cestelli Guidi (Italy) Hans Minetti (Germany) Philip Gooding (United Kingdom) Christian Ostenfeld (Denmark) FIP Awards for Outstanding Concrete StructuresYears Buildings Civil Engineering 1998 The Osaka Municipal Central Gymnasium, Japan The Belfast Waterfront Hall, Northern Ireland The Normandy bridge near Le Havre, France The Great Belt East Bridge, Denmark 1994 The breakwater jetty in Sakai, Japan The tennis center of Yale University in New Haven, Connecticut, USA The administrative building of the ECC construction group in Chennai, India The Skarnsundet cable stay bridge, Norway The footbridge over the Vranov reservoir, Czech Republic 1990 La Grande Arche in Paris, France The Gullfaks C oil platform, Norway The Oosterschelde storm surge barrier, The Netherlands The pedestrian bridge across the Altmahl river at Kelheim, Germany Secretariat

The fib secretariat is headed by the secretary general and is located in Lausanne, Switzerland on the campus of the Ecole polytechnique fédérale de Lausanne (EPFL).

The secretary general provides overall guidance on the daily operations of the association and ensures coordination within the association and with partner associations.

The secretariat provides all the administrative support to the association, including membership, bulletin sales, awards and communications to carry out the directives of the presidium.

If you need information from the secretariat, do not hesistate to contact us.

Secretary General

Dr David Fernández-OrdóñezAccount and Administration Specialist

Ms. Daniele SaugyCommunications and Events Specialist

Ms. Marie ReymondWeb Development and Publications Specialist

Ms. Corinne Bottollier Dépois-

fib Secretary General

fib Communications & Events Specialist

fib Web Development & Publications Specialist

General assembly

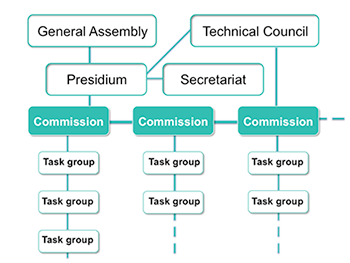

The fib general assembly (GA) consists of the heads of delegation (one per country) and the additional delegates (or their deputies) as appointed by the national groups. The number of delegates, and accordingly, the number of votes, for each national group is determined by the chosen subscription level.

The fib general assembly (GA) consists of the heads of delegation (one per country) and the additional delegates (or their deputies) as appointed by the national groups. The number of delegates, and accordingly, the number of votes, for each national group is determined by the chosen subscription level.fib members can find the current list of national groups and their respective delegates and deputies if they logged in the fib members' section of the website.

The GA meets at least once every two years and is the overriding authority of the association. It is therefore responsible for approving:

- amendments to the statutes;

- resolutions and technical conclusions, including the fib Model Code;

- voting rights of national groups;

- operating budget, accounting, membership subscriptions and other financial matters; and

- honorary members and honorary presidents

In addition, the GA elects the following members of the presidium:

- President and Deputy-President

- Honorary Treasurer

- Four elected presidium members (for a four-year term)

First name Last name Country Affiliation Antonio Martinez Cutillas Spain Carlos Fernandez Casado, S.L. Milan Kalny Czech Republic Pontex Ltd. Andrew Truby United Kingdom Truby Stevenson Ltd Roland Fox Luxembourg Admin. Ponts et Chaussées Julio Timerman Brazil IBRACON /ENGETI Avraham Dancygier Israel Technion-Israel Institute of Technology Congzhen Xiao China China Acad. Building Res. Gennadiy G. Farenyuk Ukraine NIISK - Research Inst. Building Constr. Jiri Kolisko Czech Republic Czech Technical University in Prague Kyoji Niitani Japan Oriental Shiraishi Corporation Eva Oller Ibars Spain Technical University of Catalonia Alejandro Pérez Caldentey Spain FHECOR Ingenieros Consultores/Universidad Politécnica de Madrid Jesus Gomez Hermoso Spain - Hasan Ali Karahan Turkey ITU - Istanbul Technical University, Rectorate Stathis Bousias Greece Department of Civ il Engineering David Fernández-Ordóñez Switzerland fib Jan Vítek Czech Republic Metrostav a. s. Elisabeth Hierlein Germany FDB - Fachvereinigung Deutscher Betonfertigteilbau e.V. Udo Wiens Germany DAfStb - Deutscher Ausschuss für Hans Rudolf Ganz Switzerland Ganz Consulting Stef Maas Belgium FEBE György L. Balázs Hungary Budapest Univ. of Techn. & Economics Konrad Bergmeister Austria Univ. Bodenkultur Christis Chrysostomou Cyprus Cyprus University of Technology Wit Derkowski Poland Cracow Technical University Iria Doniak Brazil ABCIC Brett Pielstick United States Eisman & Russo Alper Ilki Turkey ITU - Istanbul Technical University Akio Kasuga Japan Sumitomo Mitsui Construction Co., Ltd Yurii Kalyukh Ukraine NIISK - Research Inst of Building Constr. Jože Lopatič Slovenia University of Ljubljana Giuseppe Mancini Italy Politecnico Torino Marco Menegotto Italy Private Frank Papworth Australia BCRC Larbi Sennour United States The Consulting Engineers Gr., Inc. Dabin Feng China China Acad. Building Res. Thanasis Triantafillou Greece University of Patras Aad van der Horst Netherlands - Joost Walraven Netherlands Dutch fib Delegation Christian Cremona France Bouygues Construction Sherif Yehia United Arab Emirates Prof. Kees Blom Netherlands City of Rotterdam Owen Brooker United Kingdom Structronix Ltd Jean-François Cap Belgium SECO Bureau de contrôle tech. pour la constr. Edoardo Cosenza Italy Univ. of Napoli Federico II George Cremasco Australia Westkon Precast Concrete Pty. Ltd Carola K. Edvardsen Denmark Cowi AS Paul Gauvreau Canada University of Toronto Johan Silfwerbrand Sweden KTH Royal Institute of Technology Kim Johansson Finland Concrete Assoc. of Finland Walter Kaufmann Switzerland ETH Zürich Josef Knitl Germany Max Bögl GmbH Tamás Kovacs Hungary Budapest Univ. Technology Itai Leviathan Israel Leviathan Engineers János Magyar Hungary A-HID Epito Zartköruen Mukodo Reszvénytarsasag Viktor Markelj Slovenia Ponting d.o.o. Lars Meyer Germany Deutscher Beton- und Bautechnik-Verein Michael Pauser Austria ÖBV Andrea Prota Italy Universita di Napoli Federico II Robert Vollum United Kingdom Imperial College London Johan Paul Vyncke Belgium CSTC Limelette Anna Saetta Italy Università Iuav di Venezia Dan Georgescu Romania Techn. Univ. of Civil Engineering Nadarajah Surendran United Kingdom PRAETER Engineering Ltd Kjell Fosså Norway Kvaerner Concrete Solutions Bob Risser United States PCI Precast/Prestressed Concrete Inst. Christian Schang France SNCF RESEAU Anna Halicka Poland Lublin University of Technology Antonio Occhiuzzi Italy Istituto per le tecnologie della costruzione consiglio nazionale delle Larry Krauser United States General Technologies, Inc. Minehiro Nishiyama Japan Kyoto University Susumu Inoue Japan Osaka Institute of Technology Rayed Al Arashi United Arab Emirates Goverment of Dubai Harald Müller Germany SMP Ingenieure im Bauwesen GmbH Petr Hajek Czech Republic Czech Technical University in Prague Antonio Mari Bernat Spain Uni. Politéc. Catalunya Fernando Stucchi Brazil ABECE/EGT Giovanni Plizzari Italy University of Brescia Stephen Foster Australia UNSW Sydney Johann Kollegger Austria Vienna University of Technology Sung-Gul Hong Korea, Republic of Seoul National University Linh Hoang Denmark Danmarks Tekniske Universitet Xilin Lu China Tongji University Gregg A. Freeby United States ASBI (American Segmental Bridge Institute) Janne Kihula Finland Finnish Concrete Industry Association Denis Mitchell Canada McGill Univ. Montreal Robby Caspeele Belgium Ghent University Odinir Klein Júnior Brazil França e Associados Dmitry Kuzevanov Russian Federation NIIZHB Mikael Hallgren Sweden Tyréns Sverige AB Peter Paulik Slovakia Slovak University of Technology in Bratislava Eduardo Julio Portugal Instituto Superior Tecnico, Universidade de Lisboa Marco di Prisco Italy Politecnico di Milano Chris Hendy United Kingdom Atkins Vyatcheslav Falikman Russian Federation Russian Structural Concrete Association Tor Martius-Hammer Norway SINTEF AS Alejandro Mateos Argentina National University of Northwest of Buenos Aires - UNNOBA Wayne Kassian Canada Kassian Dyck Associates Takumi Shimomura Japan Nagaoka Univ. of Technology Agnieszka Bigaj-van Vliet Netherlands TNO - Buildings, Infrastructures and Maritime Mario Pimentel Portugal Faculty of Engineering of University of Porto Martin Moravcik Slovakia SNK fib Antoni Cladera Bohigas Spain University of Balearic Islands Luc Taerwe Belgium Ghent University Wim Jansze Netherlands Consolis Renata Kotynia Poland Lodz University of Technology Thierry Delemont Switzerland T-ingenierie SA Andreas Sjaastad Norway Veidekke Entreprenør AS Arianna Minoretti Norway Statens vegvesen Moustafa Al-Ani New Zealand - Sándor Sólyom Hungary Budapest Univ. of Techn. & Economics Jean Michel Torrenti France Univ Gustave Eiffel Sylvia Kessler Germany Helmut-Schmidt-University/ University of the Federal Armed Forces Hamburg Jongkwon Choi Korea, Republic of Hongik University Reggie H. Holt United States Federal Highway Administration Benjamin Graybeal United States Federal Highway Administration Tetsuya Ishida Japan Department of Civil Engineering Lionel Linger France Vinci Construction Grand Projets Tim Christle United States Post-Tensioning Institute Ólafur Haraldsson Iceland Icelandic Road and Coastal Administration Alok Bhowmick India B&S Engineering Consultants PVT.Ltd Anssi Laaksonen Finland Tampere University of Technology Auli Lastunen Finland - Fatma Mohamed Tanzania, United Republic of University of Dar Es Salaam Lwitiko Kalenga Tanzania, United Republic of University of Dar es Salaam Sisir Banerjee India The Institution of Engineers Marcin Górski Poland Silesian University of Technology Alberto Meda Italy University of Rome “Tor Vergata” Steve Denton United Kingdom WSP Alfred Strauss Austria BOKU University Giuseppe Loporcaro New Zealand University of Canterbury Chikako Fujiyama Japan Yokohama National University Corin Walford United Kingdom - Takafumi Noguchi Japan The University of Tokyo Sarah Skorpen South Africa University of Pretoria Josée Bastien Canada University Laval Véronique Bouteiller France University Gustave Eiffel Jonathan Mai-Nhu France CERIB José Manuel de Sena Cruz Portugal University of Minho Ana Sofia Louro Portugal LNEC Hans-Dieter Beushausen South Africa University of Cape Town Henrik Brøner Jørgensen Denmark University of Southern Denmark Alireza Khaloo Iran, Islamic Republic of Sharif University of Technology Arash Zolfagharnasab Iran, Islamic Republic of Paya Concrete and Cement Research Center Patrick Huber Austria Vienna University of Technology Steffen Marx Germany Technische Universität Dresden Peter Mark Germany Ruhr-Universität Bochum Nicholas Kyriakides Cyprus Cyprus University of Technology Bin Zhao China Tongji University Venkataramana Heggade India Indian National Academy of Engineers Þorbjörg Hólmgeirsdóttir Iceland The Icelandic Concrete Association Manish Mahendra Kothari India The Institution of Engineers (India) Technical council

The fib technical council (TC) consists of the heads of delegation of the national groups, commission chairs, presidium members, honorary presidents, the secretary general and additional members appointed by the presidium for a four-year term.

fib members can find the current list of TC members in when they are logged in the fib members section of the website.

The TC meets at least once per year and is responsible for initiating commissions and task groups, approving their terms of reference and appointing their chairs and conveners, respectively. The TC monitors the work of all the commissions and approves all recommendations, guides and manuals for publication.

The TC also makes recommendations to the presidium regarding:

- the dissemination of the results (in the form of bulletins, for example); and

- the need to put forth technical resolutions to be approved by the GA.

First name Last name Country Affiliation Iria Doniak Brazil ABCIC Hans Rudolf Ganz Switzerland Ganz Consulting Jim Forbes Australia Arcadis Gordon Clark United Kingdom Consultant Larbi Sennour United States The Consulting Engineers Gr., Inc. Avraham Dancygier Israel Technion-Israel Institute of Technology Roland Fox Luxembourg Admin. Ponts et Chaussées David Fernández-Ordóñez Switzerland fib Steinar Helland Norway S Helland Konsult Johan Silfwerbrand Sweden KTH Royal Institute of Technology Antonio Martinez Cutillas Spain Carlos Fernandez Casado, S.L. György L. Balázs Hungary Budapest Univ. of Techn. & Economics Jean Michel Torrenti France Univ Gustave Eiffel Konrad Bergmeister Austria Univ. Bodenkultur Christis Chrysostomou Cyprus Cyprus University of Technology Wit Derkowski Poland Cracow Technical University Alper Ilki Turkey ITU - Istanbul Technical University Akio Kasuga Japan Sumitomo Mitsui Construction Co., Ltd Gennadiy G. Farenyuk Ukraine NIISK - Research Inst. Building Constr. Jože Lopatič Slovenia University of Ljubljana Giuseppe Mancini Italy Politecnico Torino Marco Menegotto Italy Private Maria Rosaria Pecce Italy University of Naples Federico II Thanasis Triantafillou Greece University of Patras Aad van der Horst Netherlands - Joost Walraven Netherlands Dutch fib Delegation Rayed Al Arashi United Arab Emirates Goverment of Dubai Harald Müller Germany SMP Ingenieure im Bauwesen GmbH Michel Virlogeux France Virlogeux Consulting Tamon Ueda China Shenzhen University Fernando Stucchi Brazil ABECE/EGT Stephen Foster Australia UNSW Sydney Sung-Gul Hong Korea, Republic of Seoul National University Rolf Eligehausen Germany IWB, Universität Stuttgart Robby Caspeele Belgium Ghent University Peter Paulik Slovakia Slovak University of Technology in Bratislava Eduardo Julio Portugal Instituto Superior Tecnico, Universidade de Lisboa Marco di Prisco Italy Politecnico di Milano Chris Hendy United Kingdom Atkins Vyatcheslav Falikman Russian Federation Russian Structural Concrete Association Tor Martius-Hammer Norway SINTEF AS Michael Fardis Greece University of Patras Agnieszka Bigaj-van Vliet Netherlands TNO - Buildings, Infrastructures and Maritime Alberto Meda Italy University of Rome “Tor Vergata” Alfred Strauss Austria BOKU University Luc Taerwe Belgium Ghent University Xilin Lu China Tongji University Antonio Caballero Switzerland Consultant Wayne Kassian Canada Kassian Dyck Associates José Campos e Matos Portugal University of Minho Thierry Delemont Switzerland T-ingenierie SA Hugo Corres Spain FHECOR Ingenieros Consultores Domenico Asprone Italy University of Naples Federico II Linh Hoang Denmark Danmarks Tekniske Universitet Sylvia Kessler Germany Helmut-Schmidt-University/ University of the Federal Armed Forces Hamburg Tetsuya Ishida Japan Department of Civil Engineering Tor Ole Olsen Norway T.O.Olsen AS Ólafur Haraldsson Iceland Icelandic Road and Coastal Administration Alok Bhowmick India B&S Engineering Consultants PVT.Ltd Moustafa Al-Ani New Zealand - Auli Lastunen Finland - Marcelo Melo Brazil Casagrande Engenharia Fatma Mohamed Tanzania, United Republic of University of Dar Es Salaam Alejandro Mateos Argentina National University of Northwest of Buenos Aires - UNNOBA Dan Georgescu Romania Techn. Univ. of Civil Engineering Steve Denton United Kingdom WSP Sarah Skorpen South Africa University of Pretoria Josée Bastien Canada University Laval Véronique Bouteiller France University Gustave Eiffel Jan Vítek Czech Republic Metrostav a. s. Henrik Brøner Jørgensen Denmark University of Southern Denmark Alireza Khaloo Iran, Islamic Republic of Sharif University of Technology Congzhen Xiao China China Acad. Building Res. Oguzhan Bayrak United States Univ. of Texas at Austin Manish Mahendra Kothari India The Institution of Engineers (India) Presidium

The presidium consists of the president, the deputy president, the immediate past president, four elected members, two elected deputy chairs of the technical council, the secretary general (ex officio) and up to two co-opted members. The co-opted members are elected by the presidium on the recommendation of the president for the duration of his or her time in office.

The presidium meets several times per year and acts as the association’s executive committee. It is responsible for the technical promotion of structural concrete through the association’s governing bodies. In order to achieve its objectives, the presidium may delegate special tasks to ad hoc committees. The presidium is also charged with:

- selecting the venue and date of fib events (congresses, symposia, etc.);

- approving support of non-fib events;

- sets the conditions for membership and approves new members;

- grants awards, honorary memberships and medals of merit;

- appoints the secretary general and the editor-in-chief of the fib’s Structural Concrete journal; and

- issues directives and/or detailed regulations for all aspects not covered by the statutes.

President

The president is elected by the GA for two years and should already have served as deputy president for the preceding two years. Following his or her term as president, he or she will serve as the immediate past president for a further two years.

Deputy President

The deputy president is elected by the GA for two years.

President

Iria Doniak - Brazil

Past President

Stephen Foster - Australia

Deputy President

Agnieszka Bigaj Van Vliet - Netherlands

Presidium Member

Marco di Prisco - Italy

Presidium Member

Larbi Sennour - USA

Presidium Member

Jean Michel Torrenti - France

Presidium Member

Sylvia Kessler - Germany

Presidium Member

Alberto Meda - Italy

Presidium Member

Alfred Strauss - Austria

Presidium Member

Steve Denton - United Kingdom

Presidium Member

Tetsuya Ishida - Japan

Secretary General

David Fernández-Ordóñez - Spain

Guest

Hans Rudolf Ganz - Germany

Guest

György Balázs - Hungary

Guest

Luc Taerwe - Belgique

Guest

Marcelo Melo - BrazilCOM10: Model Codes

Motivation

A central aspect within the mission of the fib is the release of model codes on concrete structures and related subjects. These codes should serve worldwide as the guiding science-based documents offering in a code-type version the state of the art knowledge on the planning, design, construction, execution, operation or in service performance, maintenance, rehabilitation and dismantlement or reuse of new and existing concrete structures, respectively. The model codes should meet the latest requirements and technologies in view of aspects related to safety, serviceability, durability, sustainability of structures, recognizing economic, aesthetic and other needs of different societies.

Scope and objective of technical work

The work on the Model Code (2020) was then completed in 2023. However, in 2020, during the revision of the Model Code, the world took a major turn toward carbon neutrality. And this had a major impact on our Model Code. Basically, the three main pillars of the Model Code (2020) are sustainability, a performance-based approach, and addressing new and existing structures. In the Model Code, consideration is given to low-carbon and decarbonization of concrete structures, but carbon neutrality has many uncertainties. Therefore, the Model Code (2020) needs to be maintained to update and respond to the changing situation regarding structural concrete in the future.

The mission of the second phase of COM10 is, first, to capture new knowledge on structural concrete, trends toward low-carbon and decarbonization, etc. in each of the fib committees and consolidate them in COM10 for the future edition of the Model Code. Then, improvements and supplementary rules for the Model Code will be considered by COM10 and fed back from the Task Groups and Commissions to the members. The second is to use the Model Code (2020) for actual structures and to discuss in COM10 any modifications or design or construction that may be necessary. Therefore, TG10.1, which has completed its role, has been be disbanded and two new task groups, TG10.2 and TG10.3, are formed. TG10.2 will update MC(2020) together with the respective commissions and task groups. TG10.3 will also attempt to put MC(2020) into practice by creating examples of application of the MC(2020), prepared by the YMG in collaboration with several senior engineers.

First name Last name Country Affiliation György L. Balázs Hungary Budapest Univ. of Techn. & Economics David Fernández-Ordóñez Switzerland fib Akio Kasuga Japan Sumitomo Mitsui Construction Co., Ltd Jean Michel Torrenti France Univ Gustave Eiffel Alberto Meda Italy University of Rome “Tor Vergata” Hans Rudolf Ganz Switzerland Ganz Consulting Alfred Strauss Austria BOKU University Larbi Sennour United States The Consulting Engineers Gr., Inc. Marco di Prisco Italy Politecnico di Milano Agnieszka Bigaj-van Vliet Netherlands TNO - Buildings, Infrastructures and Maritime Luc Taerwe Belgium Ghent University Domenico Asprone Italy University of Naples Federico II Antonio Caballero Switzerland Consultant José Campos e Matos Portugal University of Minho Stephen Foster Australia UNSW Sydney Marcelo Melo Brazil Casagrande Engenharia Iria Doniak Brazil ABCIC Sylvia Kessler Germany Helmut-Schmidt-University/ University of the Federal Armed Forces Hamburg Steve Denton United Kingdom WSP Oguzhan Bayrak United States Univ. of Texas at Austin Wit Derkowski Poland Cracow Technical University Ehab Hamed Australia UNSW Australia -

TG10.2 - Model Codes Updating

The primary aim of TG10.2 is to systematically update and enhance the fib Model Code in line with advancements in materials, technology, and structural design. This process ensures the Model Code stays relevant, addressing the evolving demands of the concrete industry. The updates focus on incorporating innovations that improve structural and environmental performance while supporting the fibʼs sustainability goals.

Key areas for future development of the Model Code include:

- Incorporation of innovation in materials, design and construction: enabling the replacement of traditional materials (including concrete, reinforcing materials, and intervention materials), design concepts, and construction processes with innovative materials, technologies, and structural design solutions that offer enhanced performance, sustainability, and resilience.

- Service life extension and optimization: maximizing the overall efficiency and extending the service life of existing structures through advanced assessment methods and improved life-cycle management processes, allowing structures to perform optimally for longer and become more resilient to future demands.

- Integration of supporting technologies: facilitating the effective use of supporting technologies, such as testing, sensing, and Building Information Modelling (BIM), which present significant potential for integration, particularly in enhancing flexibility, adaptability, and circularity in concrete structures.

-

WP10.2.1 - fib Guideline for Design of Structures with Alternative Binder ConcretesConcrete is one of the most essential and versatile materials in modern society. Its strength, durability, and adaptability make it a fundamental element in the built environment, from critical infrastructure and buildings to pavements and decorative applications. With proper design and maintenance, concrete structures can last for decades, or even centuries, providing resistance to weathering, erosion, and fire. Its indispensability in construction is beyond question.ScopeThis project will involve the development of a Guideline for the Design of Structures with Alternative Binder Concretes, intended to support the safe and effective use of low-carbon concretes in structural applications. The Guideline will set out technical requirements and provide practical guidance for the future design and construction of concrete incorporating alternative binder combinations as substitutes for ordinary Portland cement (OPC).

First name Last name Country Affiliation David Fernández-Ordóñez Switzerland fib Stephen Foster Australia UNSW Sydney Ehab Hamed Australia UNSW Australia Agnieszka Bigaj-van Vliet Netherlands TNO - Buildings, Infrastructures and Maritime Akio Kasuga Japan Sumitomo Mitsui Construction Co., Ltd

First name Last name Country Affiliation David Fernández-Ordóñez Switzerland fib Agnieszka Bigaj-van Vliet Netherlands TNO - Buildings, Infrastructures and Maritime Gerrie Dieteren Netherlands TNO Andri Setiawan United Kingdom Imperial College London Ehab Hamed Australia UNSW Australia Carmen Andrade Spain Centre Internacional de Mètodes Numèrics en l’Ènginyeria (CIMNE) Ki Yong Ann Korea, Republic of Hanyang University Domenico Asprone Italy University of Naples Federico II György L. Balázs Hungary Budapest Univ. of Techn. & Economics Oguzhan Bayrak United States Univ. of Texas at Austin Konrad Bergmeister Austria Univ. Bodenkultur Mouna BOUMAAZA France Vinci Construction Véronique Bouteiller France University Gustave Eiffel Antonio Caballero Switzerland Consultant José Campos e Matos Portugal University of Minho Robby Caspeele Belgium Ghent University Hugo Corres Spain FHECOR Ingenieros Consultores Albert De la Fuente Spain Universitat Politècnica de Catalunya Marco di Prisco Italy Politecnico di Milano Michael Fardis Greece University of Patras Stephen Foster Australia UNSW Sydney Paolo Franchin Italy Sapienza Università di Roma Chikako Fujiyama Japan Yokohama National University Hans Rudolf Ganz Switzerland Ganz Consulting Petr Hajek Czech Republic Czech Technical University in Prague Michael Haist Germany - Venkataramana Heggade India Indian National Academy of Engineers Max Hendriks Netherlands Delft University of Technology Akio Kasuga Japan Sumitomo Mitsui Construction Co., Ltd Sylvia Kessler Germany Helmut-Schmidt-University/ University of the Federal Armed Forces Hamburg Lionel Linger France Vinci Construction Grand Projets Xilin Lu China Tongji University Stef Maas Belgium FEBE Giuseppe Mancini Italy Politecnico Torino Stijn Matthys Belgium Ghent University Alberto Meda Italy University of Rome “Tor Vergata” Harald Müller Germany SMP Ingenieure im Bauwesen GmbH Aurelio Muttoni Switzerland École polytechnique fédérale de Lausanne (EPF Lausanne) Stefano Pampanin Italy Sapienza University of Rome Rodney Paull Australia Member Concrete Institute of Australia (CIA), Chair CIA Durability Technical Committee; ACI 201 liaison member for CIA; ACI 321 liaison member Maria Rosaria Pecce Italy University of Naples Federico II Giovanni Plizzari Italy University of Brescia Norbert Randl Austria Carinthia Univ. of Applied Sciences Manu Santhanam India Department of Civil Engineering Akanshu Sharma United States Purdue University Takumi Shimomura Japan Nagaoka Univ. of Technology Alfred Strauss Austria BOKU University Fernando Stucchi Brazil ABECE/EGT Luc Taerwe Belgium Ghent University Jean Michel Torrenti France Univ Gustave Eiffel Tamon Ueda China Shenzhen University Aad van der Horst Netherlands - Jan Vítek Czech Republic Metrostav a. s. Joost Walraven Netherlands Dutch fib Delegation -

TG10.3 - Examples of the Model Code

The Model Code (2020) represents the accomplishments of extensive research, analysis, and collective expertise, embodying the most up-to-date insights and best practices in concrete engineering. This task group, aims to translate the principles outlined in the Model Code (2020) into tangible examples that will serve as guidance for professionals and practitioners across the globe. The efforts are to enhance the understanding and application of the Model Code.

The task group aims to develop examples that comprehend a diverse array of challenges and scenarios encountered in real-world applications. These examples will not only illustrate the principles espoused by the Model Code but also provide practical insights for structural engineers.

The TG10.3 will focus on developing real design examples derived from the fib Model Code (2020). Examples will cover various aspects of structural design practices as outlined in the Model Code. The examples will address a wide range of challenges and scenarios encountered in real-world applications of concrete design.

The objectives will guide the task group to develop examples that demonstrate the principles and best practices outlined in the fib Model Code, ultimately contributing to disseminate best practices in structural design.

The work in TG10.3 is currently carried out in the following Working Groups:

- TG10.3 WG1 - General Design – Convener: Daniel Miranda

- TG10.3 WG2 - Assessment of Existing Structures – Convener: Patrick Valeri

- TG10.3 WG3 - Design of FRC – Convener: Andrea Monserrat

- TG10.3 WG4 - Embedded FRP – Convener: Szinvai Szabolcs

- TG10.3 WG5 - Recycled Aggregates – Convener: Nikola Tosic

First name Last name Country Affiliation David Fernández-Ordóñez Switzerland fib Motohiro Ohno Japan The University of Tokyo Andri Setiawan United Kingdom Imperial College London Petar Bajic Spain - Agnieszka Bigaj-van Vliet Netherlands TNO - Buildings, Infrastructures and Maritime Hugo Corres Spain FHECOR Ingenieros Consultores Albert De la Fuente Spain Universitat Politècnica de Catalunya Morten Engen Norway Multiconsult AS Irene Josa United Kingdom University College London (UCL) Sachinthani Karunarathna Australia Arup Alio Kimura Brazil TQS Odinir Klein Júnior Brazil França e Associados Juan Mauricio Lozano Valcarcel Germany Technical University of Munich Adriana Patricia Abrahao Brazil TQS Caterina Rovati Switzerland Meyer Bauingenieure AG Daniel Miranda Brazil University of São Paulo Fernando Stucchi Brazil ABECE/EGT Nikola Tošić Spain Universitat Politècnica de Catalunya Patrick Valeri Lorenzo Switzerland Dr. Lüchinger+Meyer Bauingenieure AG Szabolcs Szinvai Hungary BME Alejandro Nogales Spain - Andrea Monserrat López Spain Universitat Politècnica de Catalunya Ligia Doniak Brazil - Stanislav Aidarov Spain - Rob Vergoossen Netherlands Haskoning Lisbel Rueda García Spain ICITECH, Universitat Politecnica de Valencia André Furtado Portugal Instituto Superior Tecnico, Universidade de Lisboa Juan Garzón Netherlands TNO Annkathrin Sinning Germany - Emilio Burgueño Argentina BCD Ingeniería Sergio Rodriguez Spain - ab van den bos Netherlands NLyse Mauricio Ferreira Brazil Universidade Federal do Parã Marcelo Melo Brazil Casagrande Engenharia Sam Chen Australia - Hisham Hafez United Kingdom University of Leeds

-